SUCCESS STORIES

Trusted in industrial applications worldwide, we provide bolting solutions to many industries and we are proud to showcase some of our success stories.

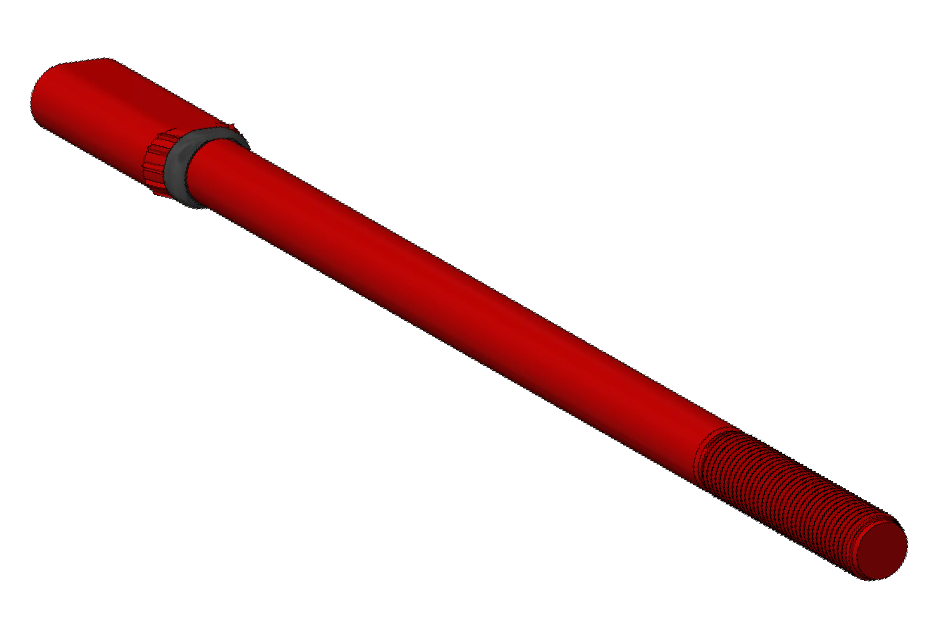

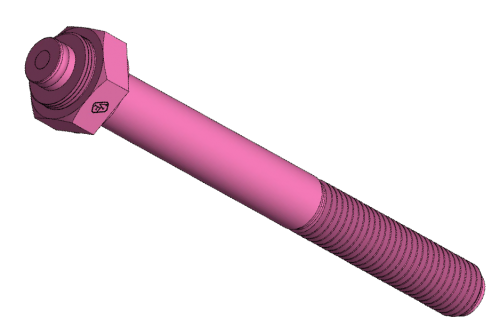

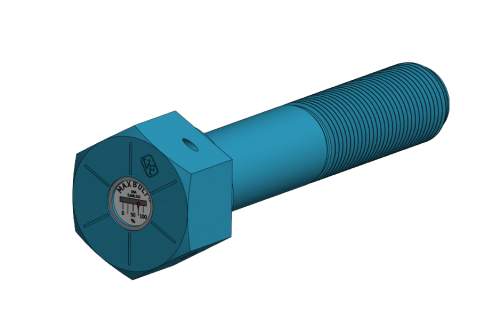

A loose bolt problem is solved for a mining operator in South Australia. Using Valley Forge & Bolt Mfg. Co. patented SPC4™ load verifying critical fasteners as direct replacements for the radial flange and trunnion bolts at both the feed and discharge ends of the autogenous grinding mill per the OEM’s specifications. Along with SPC4-404A electronic load reader, SPC4-500A mechanical load reader and SPC4-702 wireless transmitters, designed to provide real-time bolt load directly to the sites mill monitoring control room dashboard.

Recurring leaks from a problem flange. The flange was frequently repaired, only to begin leaking again within 2 weeks. Fugitive Emissions from recurring flange leaks.

Broken bolts on grate liners causing multiple unscheduled downs per month. Unscheduled down time cut into production numbers, lost time, and lost revenue.

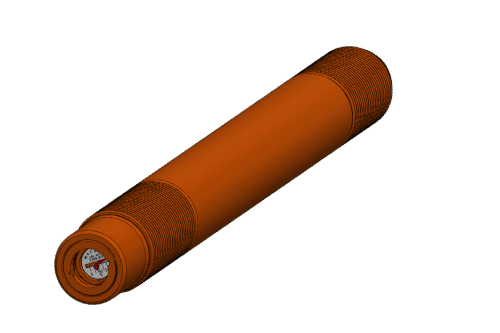

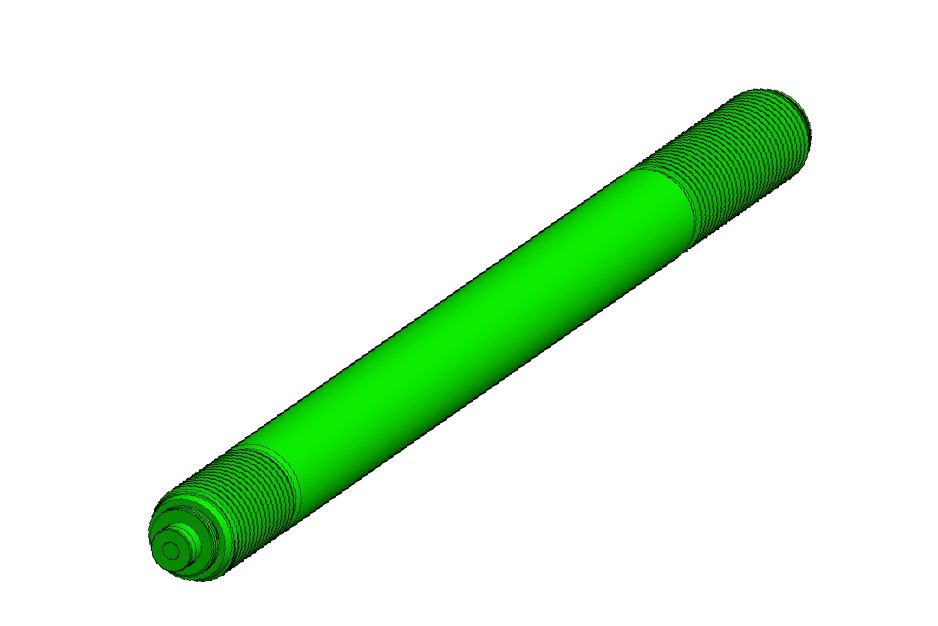

This application is for case studs in a split case compressor. Bottom B of the case has studs threaded into it around the edge of the casting. Top A is lowered onto the case (and protruding studs), then nuts are used to tighten the studs.In-between Bottom B of the centrifugal pump case and Top A is a gasket. It is imperative to have the proper load to compress the gasket and create a seal. Improper load on studs leads to improperly compressed gaskets and poor sealing on the split case pump.

Standard studs require biannual maintenance checks, which consist of each stud being re-torqued to verify clamp load. This is a difficult, labor intensive process that can be drastically improved through the use of load indicating fasteners.

Constant loosening from vibration resulting in bolt breakage, which is especially hazardous within the railcar industry. Bolt breakage can result in catastrophic equipment damages, it and poses enhanced risks to public safety.